Estimating Air Leakage Through Doors For Smoke Control

The test procedure prescribes that during test the gap between the bottom edge of the door leaf and the floor or threshold is sealed.

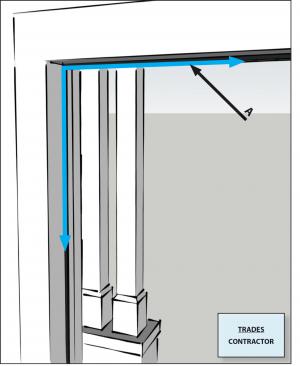

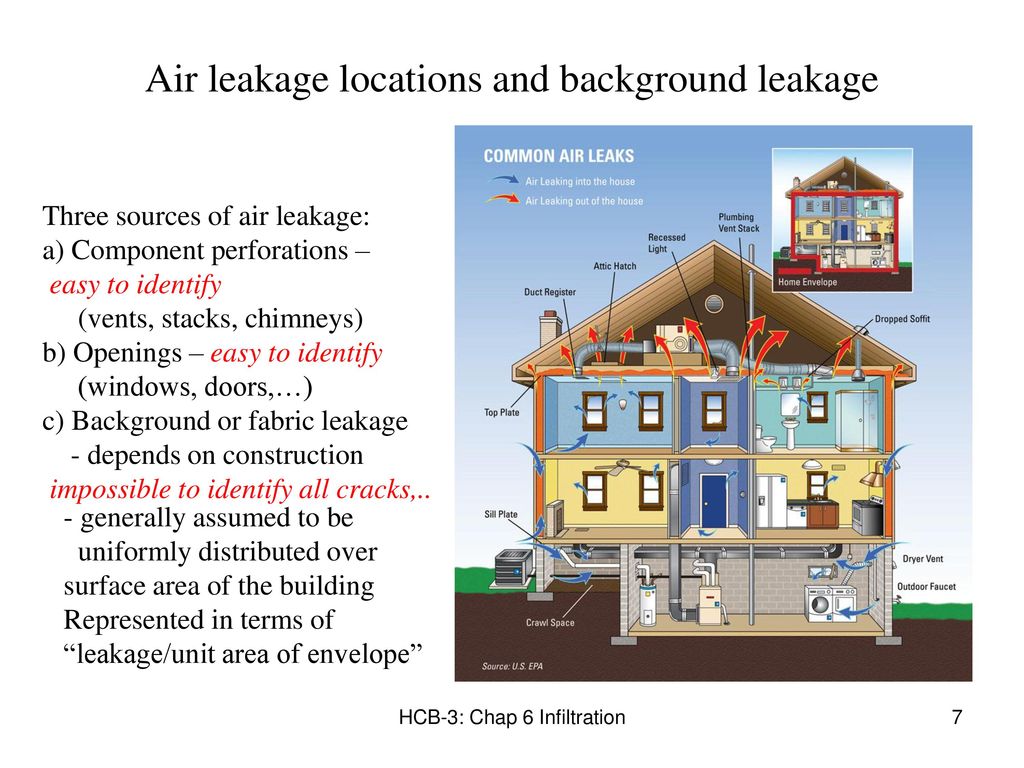

Estimating air leakage through doors for smoke control. Nondimensional relationship for flow through defined narrow gaps is used to predict leakage flow past closed door assemblies. The smoke leakage control of. Prediction of the flow of air through gaps around exterior doors is of considerable importance in determining ventilation rates and heat losses in buildings. Baffle at leading edge.

A generalized nondimensional relationship for flow through defined narrow gaps is used to predict leakage flow past closed door assemblies. And filament brush seal. Estimating air leakage through doors for smoke control. Fire safety journal 17 1991 171 177 estimating air leakage through doors for smoke conirolt daniel gross center for fire research national institute of standards and technology gaithersburg maryland 20899 usa abstract a generalized nondimensional relationship for flow through defined narrow gaps is used to predict leakage flow past closed door assemblies.

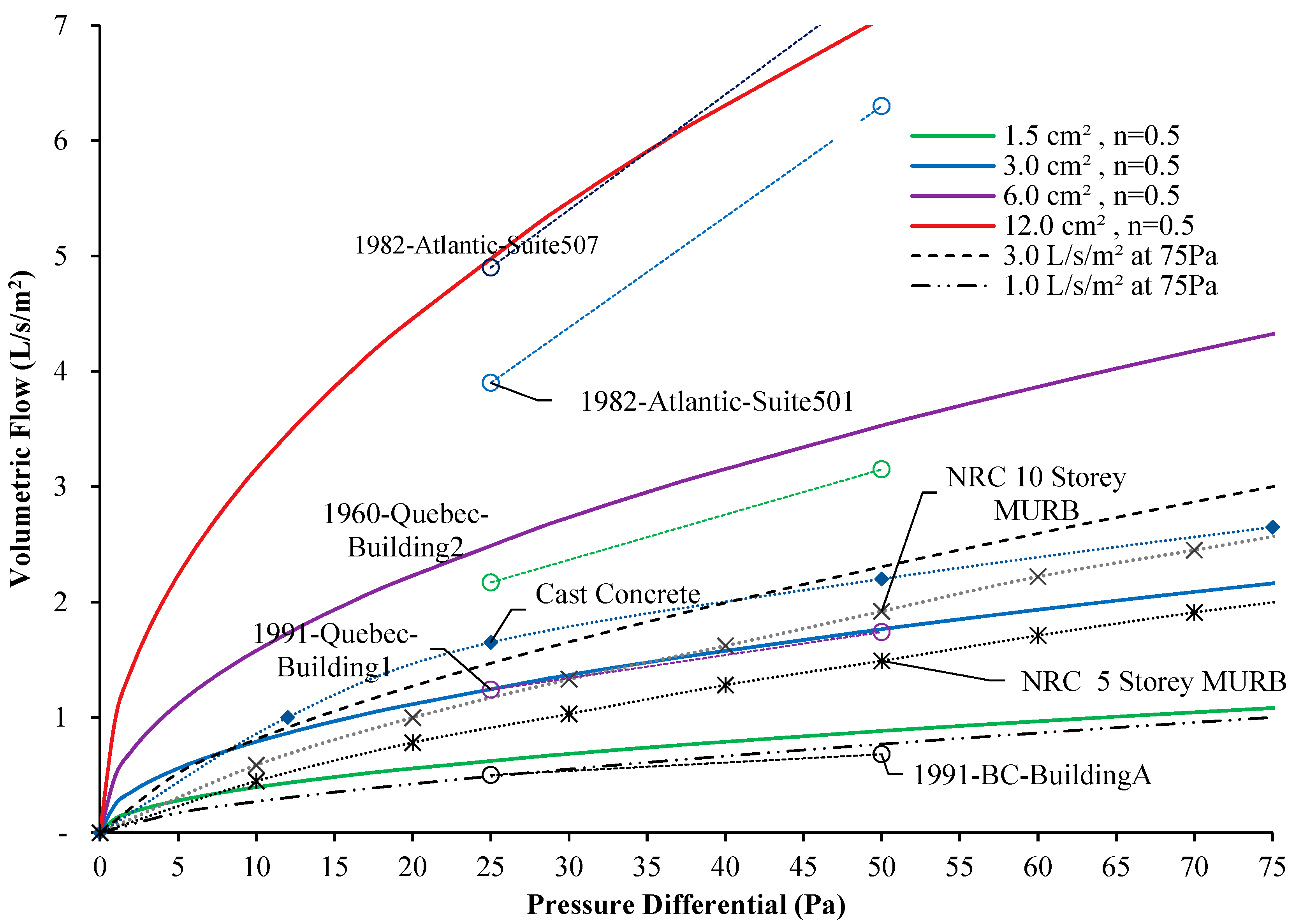

Typical gap shapes considered include straight through. Single or double sharp 90 bends. The smoke control criterion required in the united kingdom is 3m3 of air loss per hour per linear metre of joint between door leaves and the doorframe or transom when measured at 25pa pressure. Applications for prediction and design appropriate to smoke control systems are indicated.

And filament brush seal. Realistic smoke leakage control was investigated using actual scale through penetration firestop models installed in a curtain wall and air leakage measurement units. Single or double sharp 90 bends.