Ethanol Storage Tanks Nitrogen Blanketing

Ethanol storage tanks nitrogen blanketing.

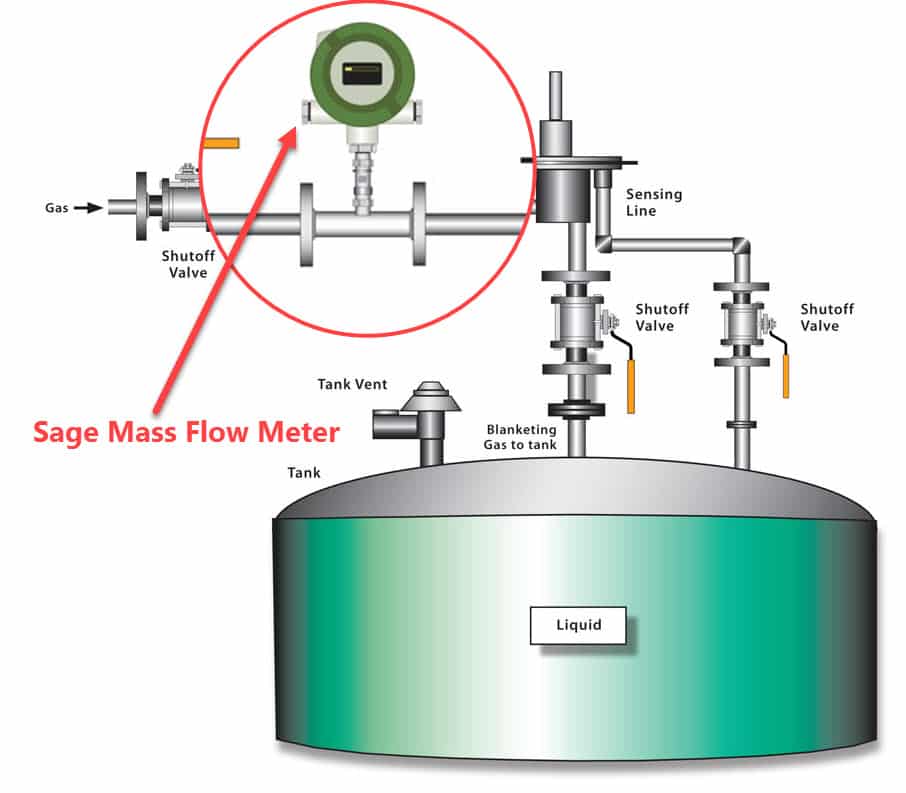

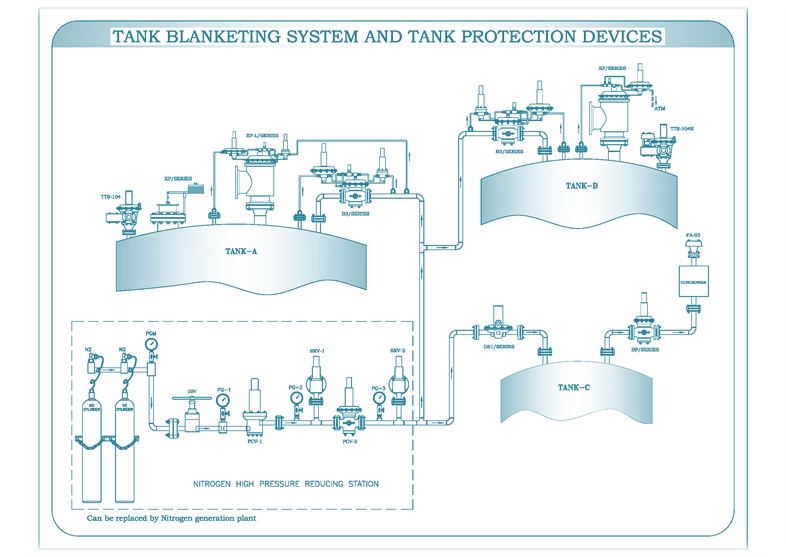

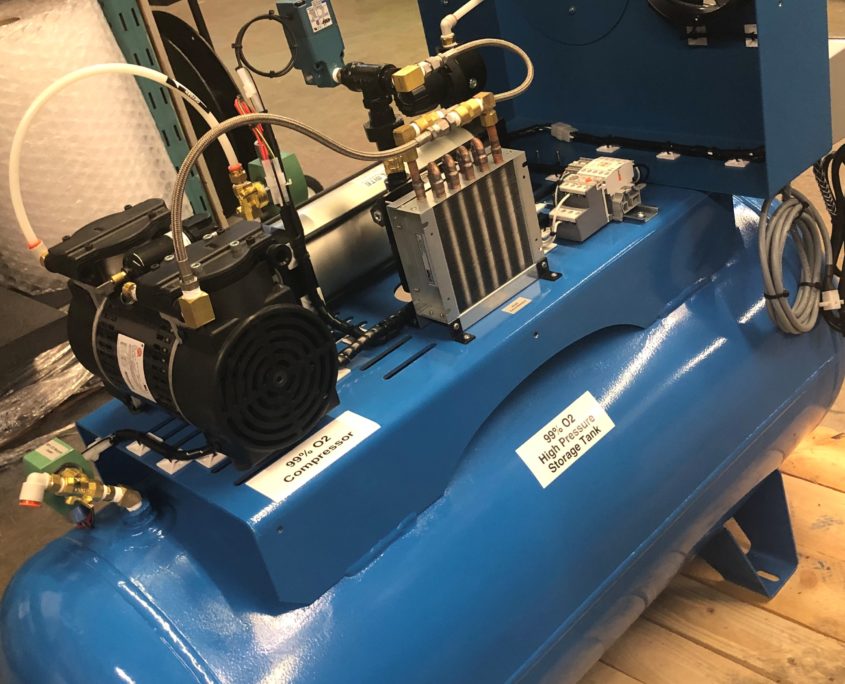

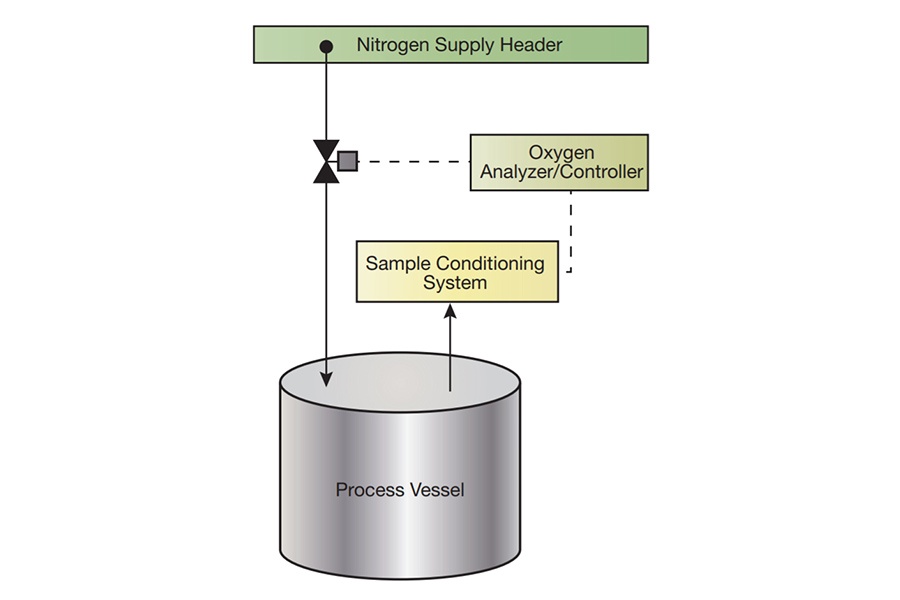

Ethanol storage tanks nitrogen blanketing. Nitrogen n2 blanketing is a process by which nitrogen is added to fill the headspace the area between the fill line of a tank s contents and the top of the storage vessel to eliminate oxygen and moisture from storage tanks. Tank blanketing nitrogen blanketing or tank padding is a process of introducing an inert gas such as nitrogen the most cost effective to a storage tank to counter the effects of oxygen on the storage material which is usually a liquid. In a technique called chemical tank blanketing or padding nitrogen is commonly applied to protect chemicals stored in tanks against contamination degradation or chemical change as well as to prevent fire or explosions. Nitrogen blanketing and tank from refinery to delivery trucks tank blanketing basics covered safety nitrogen tank.

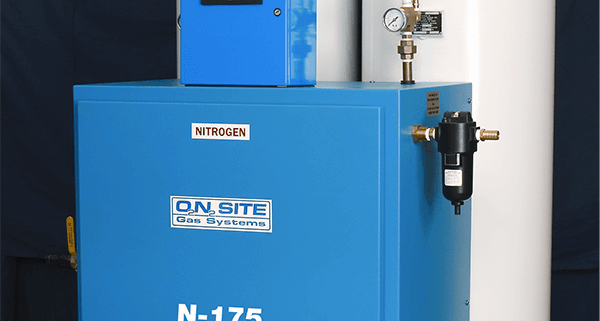

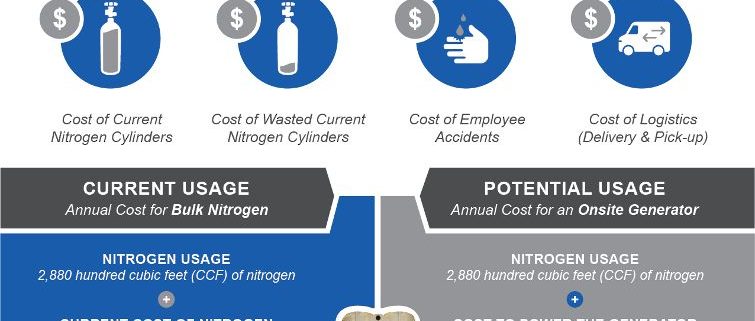

In 1999 the first purpose built. Methanol ocean tankers and nitrogen inerting cont n2 generators were not practically available at a cost and size that made sense so the smaller tank solution was a sensible alternative. Prev article next article. Nitrogen is commonly used to blanket due to its extremely low reactivity with other substances as well as its availability and relatively low cost.

As n2 generators became more available in the 90 s interest peaked with methanol products. Ethanol storage tanks nitrogen blanketing. Jc alberro 2 years ago no comments.