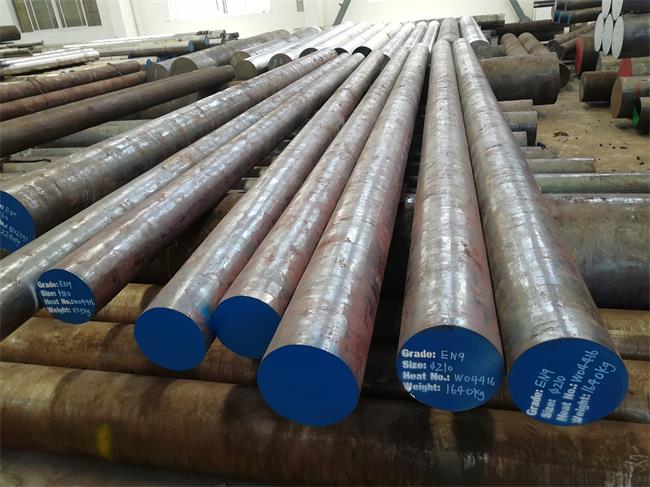

Flame Hardening Steel Grades

As its name suggests flame hardening uses direct heat from oxy gas flames.

Flame hardening steel grades. Depending on the amount of time and temperature the affected area can vary in carbon content. Carburising carburizing chiefly american english or carburisation is a heat treatment process in which iron or steel absorbs carbon while the metal is heated in the presence of a carbon bearing material such as charcoal or carbon monoxide the intent is to make the metal harder. The component is fixtured to the spin table and torch heads are adjusted to ensure proper. Factors that affect the depth of hardness achievable in steels and relationships between hardness and tensile strength are also outlined.

Process of flame hardening 4140 other steel grades of machined parts and stampings. To harden steel start by heating the metal directly with a blow torch until it turns a cherry red color. The process of flame hardening. Flame hardening sometimes begins with a preheat operation depending on the alloy and degree of machining.

Flame hardening is similar to induction hardening in that it is a surface hardening process. Heat is applied to the part being hardened using an oxy acetylene or similar gas flame on the surface of the steel being hardened and heating the surface above the upper critical temperature before quenching the steel in a spray of water. Hold the steel directly in the flame. Below is an outline of the process that follows thereafter.

The hardness of steels can be increased using various processes such as surface flame and induction hardening as well as nitriding. Keep a grade b fire extinguisher nearby in case of a fire.