Flaring Process Sheet Metal

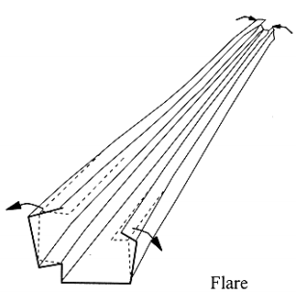

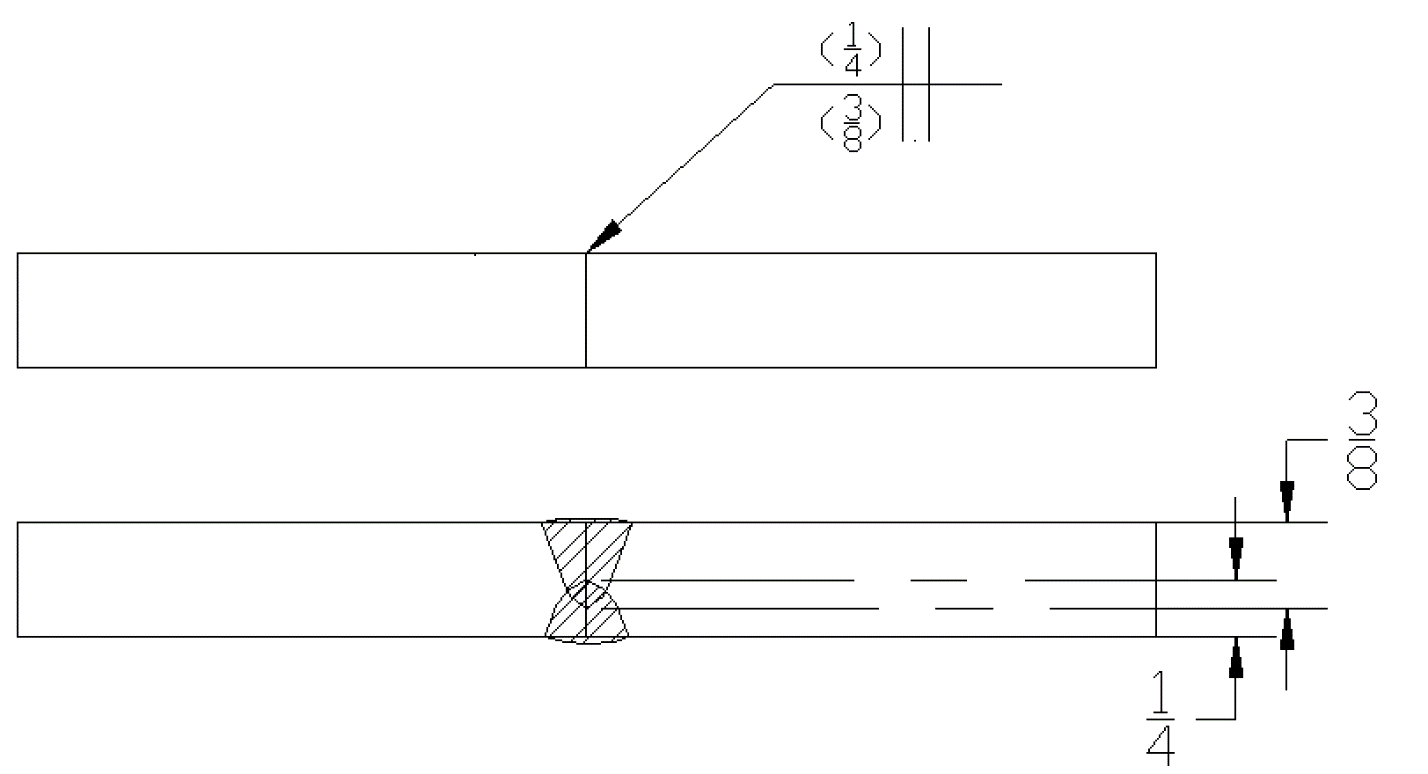

The flaring is done with a pair of rolls that travel around the hole and are fed down into the part deforming the metal in a controlled predicted way.

Flaring process sheet metal. On this page you will find a great selection of drill presses hand punches sheet metal cutters step drills and drill jigs the tools on this page are useful in many industries for creating holes in sheet metal plate channel tubing and more. They work great in our mittler bros. The pressure exerted by the press forces the punch side metal to spread outwards within the die side metal. Joints can range from 1 5 to 26 millimeters in diameter.

Tox has recently introduced a number of variations in the process. Van sant enterprises specializes in high performance metal fabrication tools and equipment. Hydroform or fluid forming process in hydroforming or fluid forming process the pressure over the rubber membrane is controlled throughout the forming cycle with. Sheet metal fabrication is the process of forming parts from a metal sheet by punching cutting stamping and bending.

Process monitoring overview clinching monitor cep pressing monitor epw. Go through sheet metal processes. The punch forces the layers of sheet metal into the die cavity. Sheet metal clinching shapes tox round joint tox skb tox twinpoint tox flat joint tox vario joint.

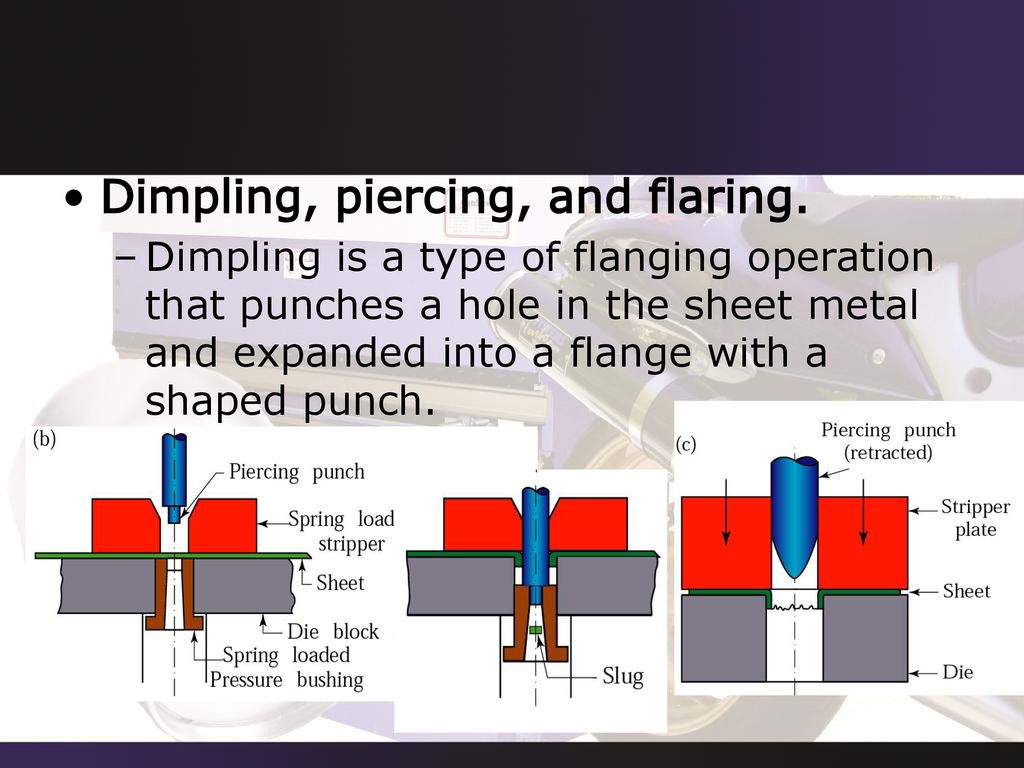

Spring back is the unwanted tendency of sheet metal to retain or go back to its original flat form after the forming process features such as collars near pierced areas also serve a purpose. Bench press or by simply placing the two halves of the die on either side of the properly sized hole drawing the tool together with a standard wrench. 16 gauge steel is the. Examples of the bending and the embossing of sheet metal with a metal punch and with a flexible pad serving as the female die lecture 05.

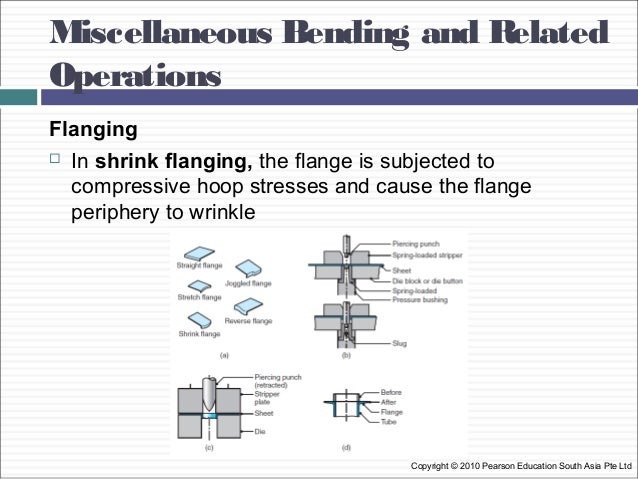

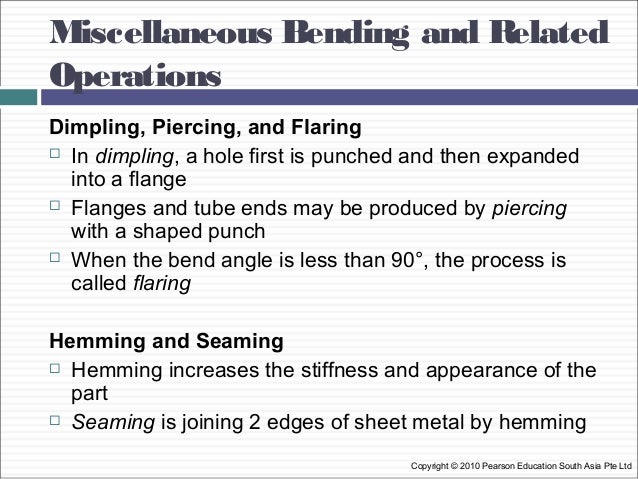

Sheet metal riveting crimping flaring. The process is called flaring hemming and seaming hemming increases the stiffness and appearance of the part seaming is joining 2 edges of sheet metal by hemming. The twinpoint tool creates two round joints side. 1 630 4474600.

Sheet metal forming processes 34 21 22. Wisconsin metal tech s metal flaring machines allow us to offer metal tube flaring deburring and a wide range of other processing finishing services in or. Grease is often used to lubricate this swaging process which is also called roller swaging. Solutions overview clinching eclinching riveting joining.